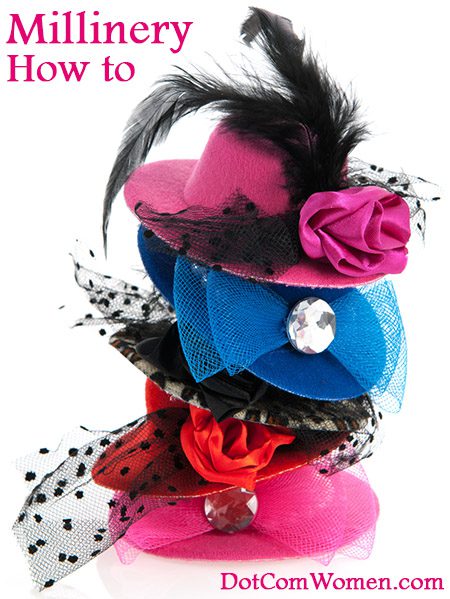

Millinery How to

The art of millinery is being rediscovered as skilled designers keep hats in the forefront of fashion. The hat industry represents a unique blend of technology and craftsmanship and millinery hats are renowned all over the world for their quality and designs. Unlike other mass-produced goods it is still labour intensive – it may surprise you to know that a hat goes through 45 processes before it is finished! Read on to take a look at some of the processes involved in creating the finished product and gain an insight into a fascinating craft.

Story Board

The hat designer has to keep abreast of forthcoming themes in fashion and colour, and focus on creating new shapes each season. He or she may make a sketch or work straight into the hat, pinning on the trimmings or draping the fabric until they are pleased with the result. Specialist suppliers provide flowers, feathers, braid etc. to give each hat individuality.

Shaping Up

Blocking is the shaping of various materials over aluminium blocks, with every style that is designed having its own block. Straw and felt arrive at the factory in a semi-shaped state, known as a ‘hood’. When blocking begins, the shape is heated by gas to a high temperature and the hoods are subjected to steam. Two people are required to stretch the fabric over the block as this involves a surprising amount of strength and accuracy. After the initial blocking and machining, hats are pressed using a hydraulic machine to give a smooth, clean finish.

Machining

A machinist plays an important part in the manufacturing process. Several types of sewing machine are used, all of which require special skills. A hat can be made entirely by machine by fixing together several pieces of fabric or cloth that have been pre-cut to pattern, and it is then that the skill of the machinist comes into play in the creation of the correct style. Another part of hat machining involves working with materials such as wool felt, straw and fabrics which have been pre-formed by the blocking process. When working with these mediums, a machinist may have to sew a wire or cane onto the edge of the brim to maintain its shape, fix crowns and brims together to create different styles or attach ribbon or velvet to the edge of the hat to give a neat, clean finish. These tasks all require a large degree of expertise, and skilled machinists are highly sought after in the millinery trade.

Trimming

After its shape, the most important part of a hat is its trim. Trimming is the process performed to embellish and give style, involving attaching a wide variety of trims around the crown and sometimes under the brim, and is also the name given to the art of cutting, measuring and making drapes and pleats. Trims are usually sewn by hand onto a hat or alternatively can be glued with a hot glue gun, as used in decorative crafts.

Passing

This is the stage where the product passes through quality control. Checks will be carried out on the hood, trim, machining and head fit, labels will be inserted and the hat will be cleaned and brushed or blown with an airgun.

Hot Potting

In order to ensure that the inner ribbon head band is pressed flat and also that the head fitting is right, the hat will be placed over a warm metal shape called a Hot Pot.

Packing

Once passing and hot potting have been successfully carried out, the hats are bagged in polythene and carefully packed in cardboard boxes with tissue paper. While this may sound relatively straightforward, packing hats is actually a specialist area requiring particular skills of judgement and knowledge acquired through experience.

Millinery Trail

Luton has long been recognised as the centre of the British hat industry. You can pick up a copy of the ‘Millinery Trail’ from The Tourist Information Centre, which includes all of the key features to been seen on a millinery tour of the town. It is also possible to make a hat purchase from one of the hat factory shops, or take a tour of a factory to witness at first hand the processes of manufacture. The Tourist Information Centre is located at 65-67 Bute Street, Luton, LU1 2EY